Product advice

Here you will find more information on the individual cutting set parts, such as holeplates, knives and supporting stars.

Pre cutters

Our sickle pre-cutters are designed so that they make a single continuous cut and offer low resistance regarding material flow!

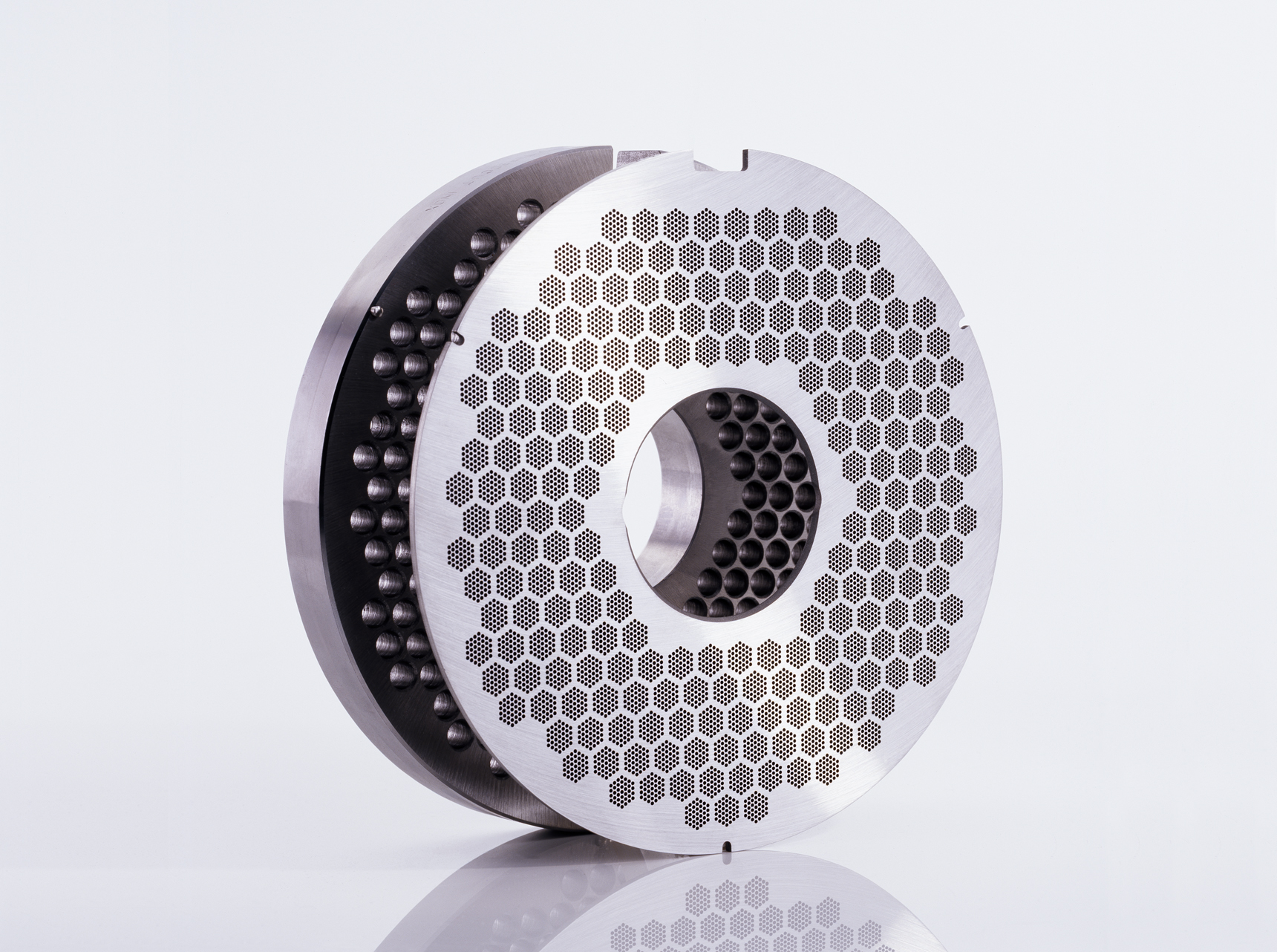

Holeplates

There are very many different designs of holeplates

- Intermediate holeplates

- Final holeplates

- Segment holeplates

- Thin holeplates + carrier plates

- Portioning holeplates

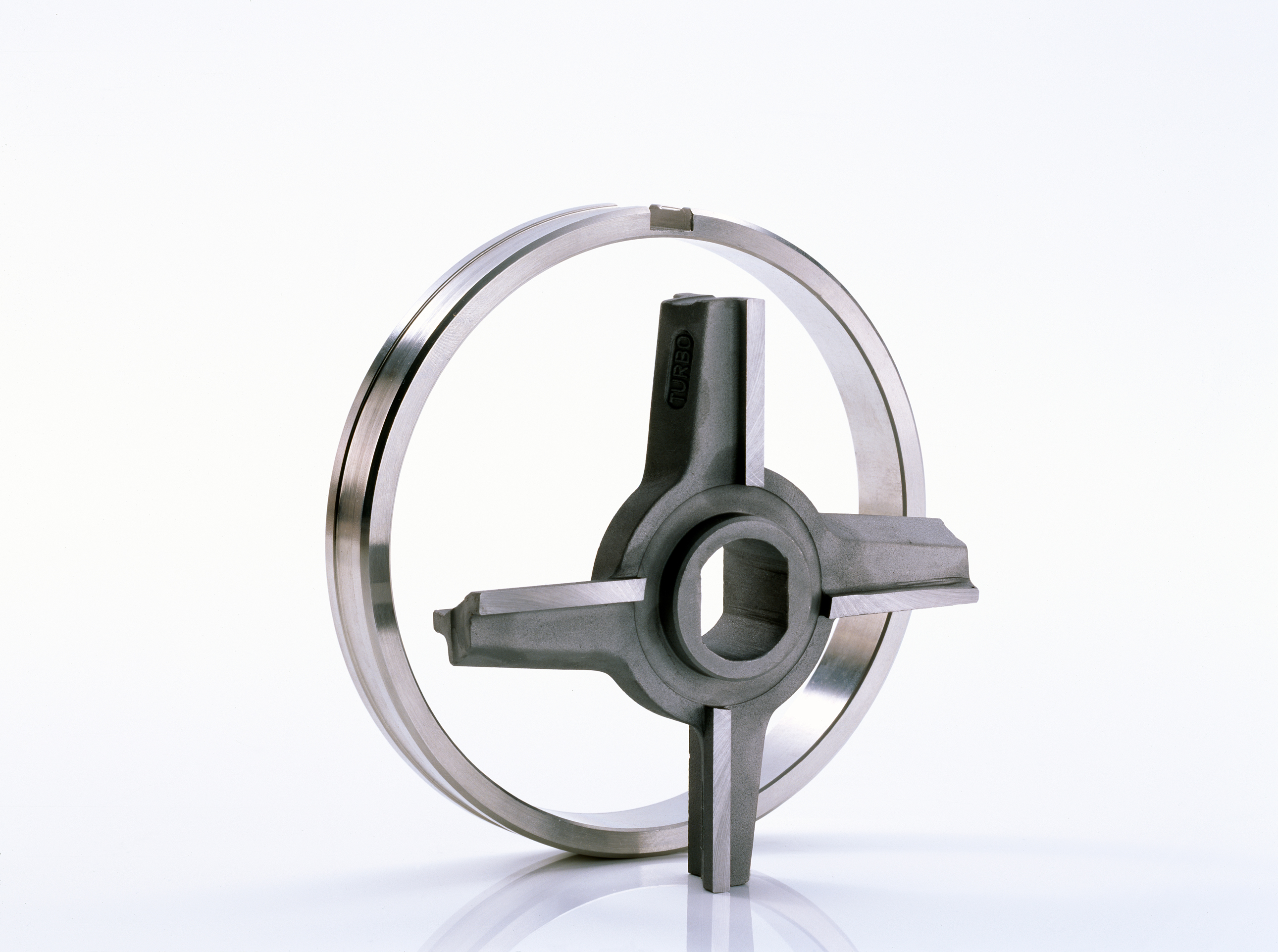

Ring knives

Ring knives have a rotating ring which is fixed to the blades, allowing for greater stability and a more delicate design of the individual arms of the knife.

Special ring knives

Our special ring knife has a special shape where half of the blades on the front have an interrupted cutting edge (= "half" blades). These special ring knives can be designed with six, eight or more blades.

The interrupted cutting edges enable the meat in the cutting chamber to be constantly mixed. The meat is processed in a gentler manner, resulting in a finer cut. Such knives are used in stuffing grinders as standard knives. A definite increase in performance (20 %) is particularly achieved in combination with our tc2 hole plates (see hole plates).

Star knives

Star knives are "standard" in our cutting sets. They can be used for various products, e.g. ground meat. We also use the star knife for the first cutting section in our separating set. Because of the very many different possible uses we have developed a complex form for our tc2 star knife which fully takes into account the necessary requirements.

turbocut tc2 star knives

- The design of the arms allows them to feed the meat gently forwards so that it is not just conveyed onwards by the pressure from the following meat.

- The slanting angle of the arms enables a better distribution of the material in the cutting chamber.

- On the rear the blades have a tapered design, making them last longer.

Distance ring knives

Separating knives

Sorting knives / separating knives / conveyor knives

Insert knives

- Pendulum insert knives

- Profile insert knives

- Insert knives

Why?

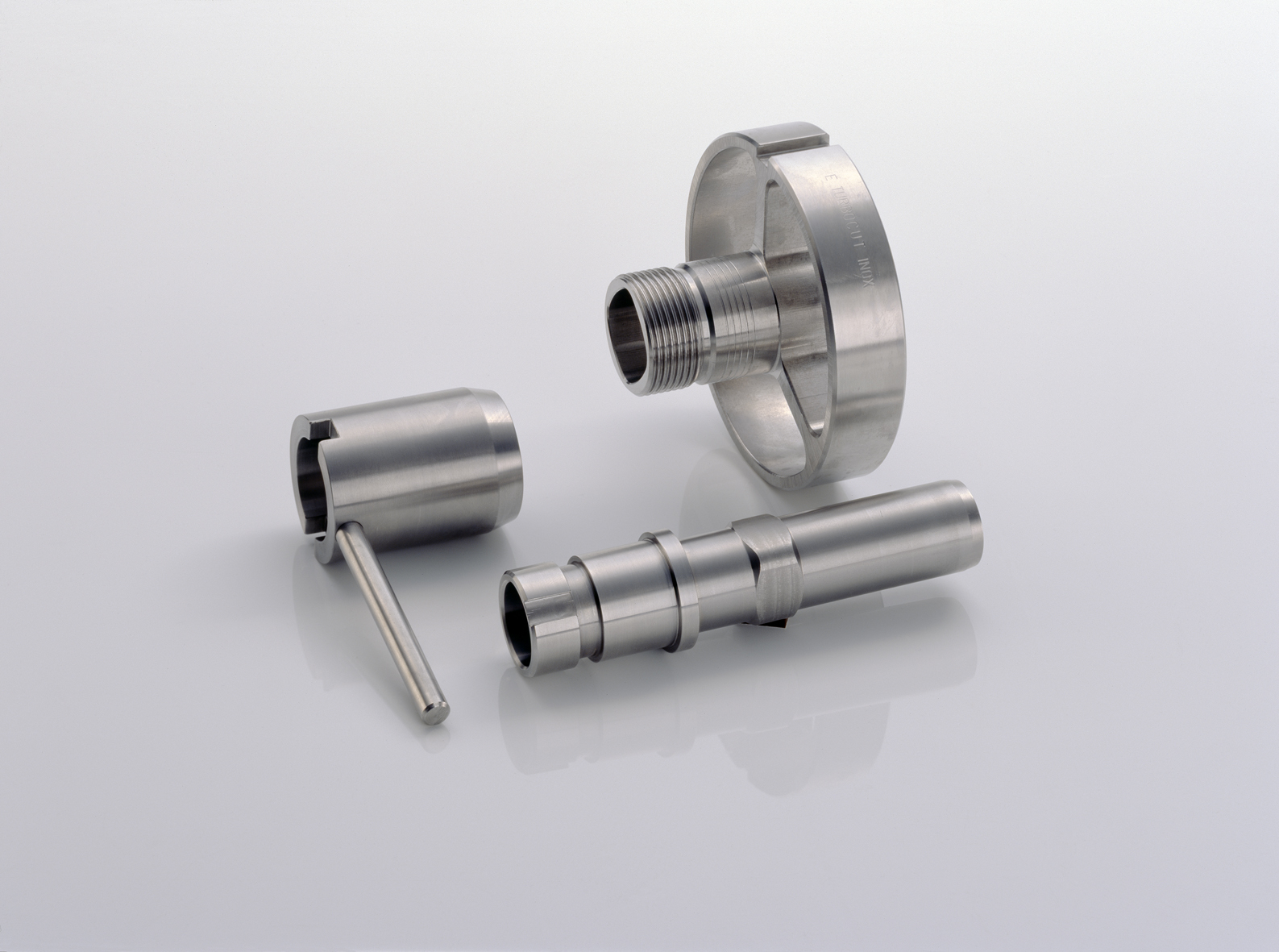

Separating device

Our separating device consists of

- Separating supporting star

- Outflow tube

- Adjustable bushing

Particularities

- Retrofitting possible for all common grinders

- Increased separating rate

- Integration possible in all cutting sets

- Use with standard plates and separating knives

- Infinitely adjustable

Separating set

Supporting stars

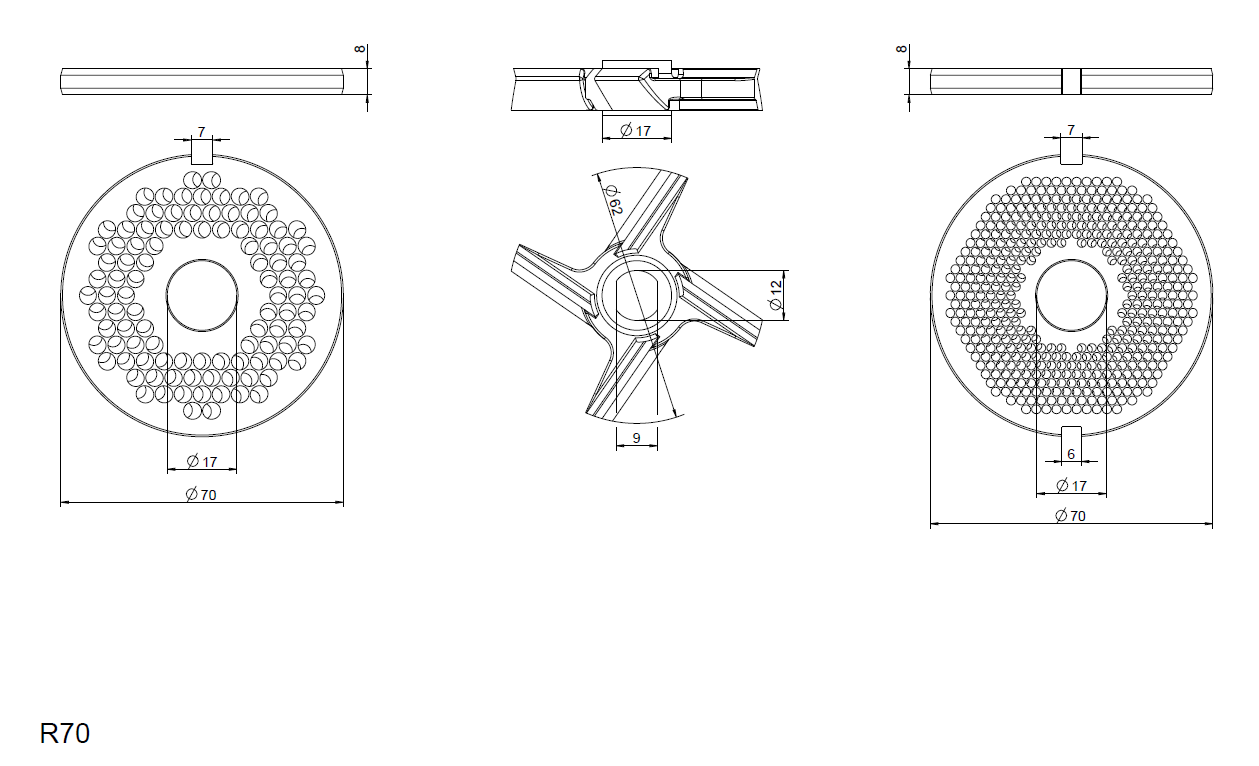

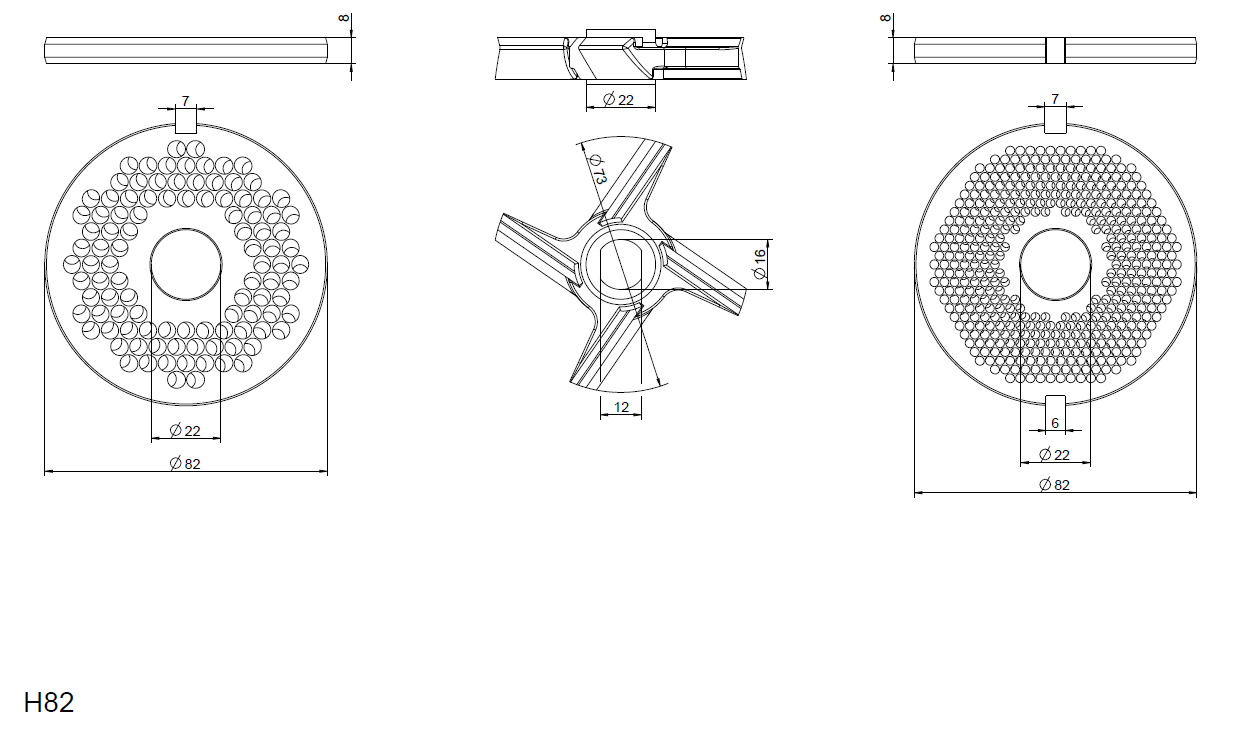

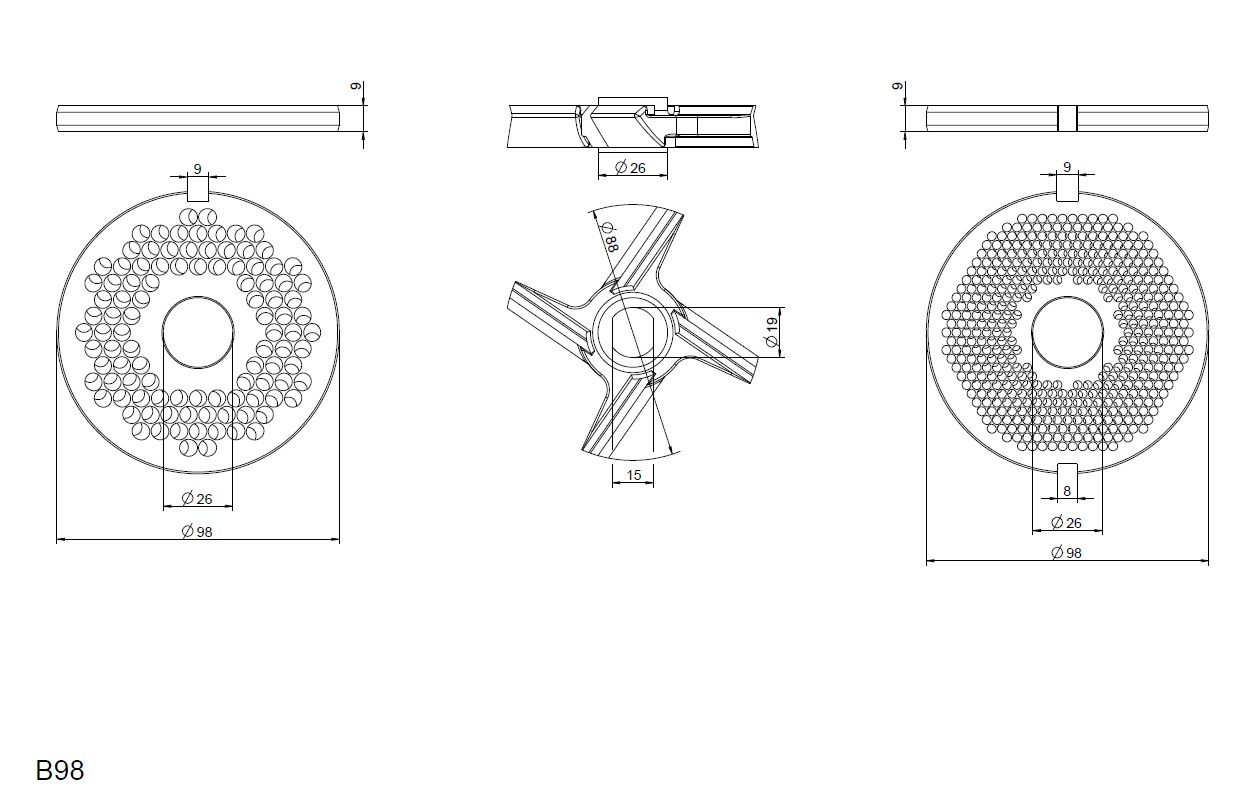

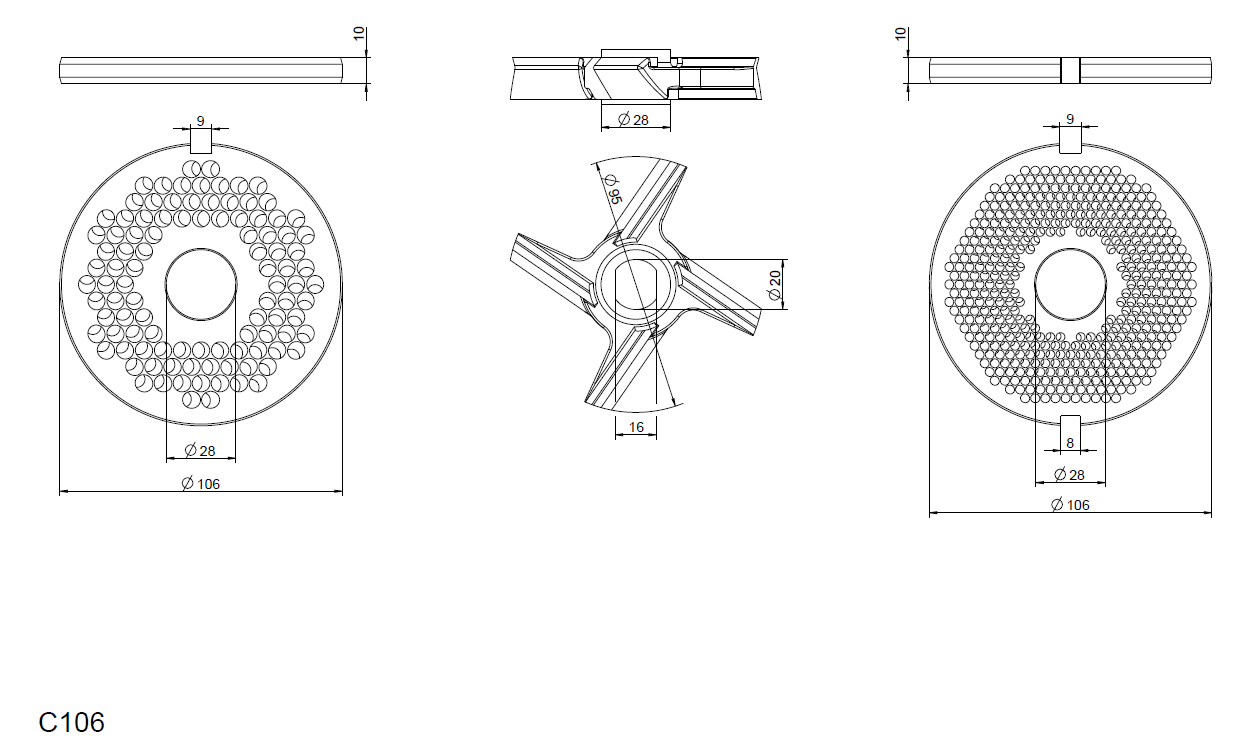

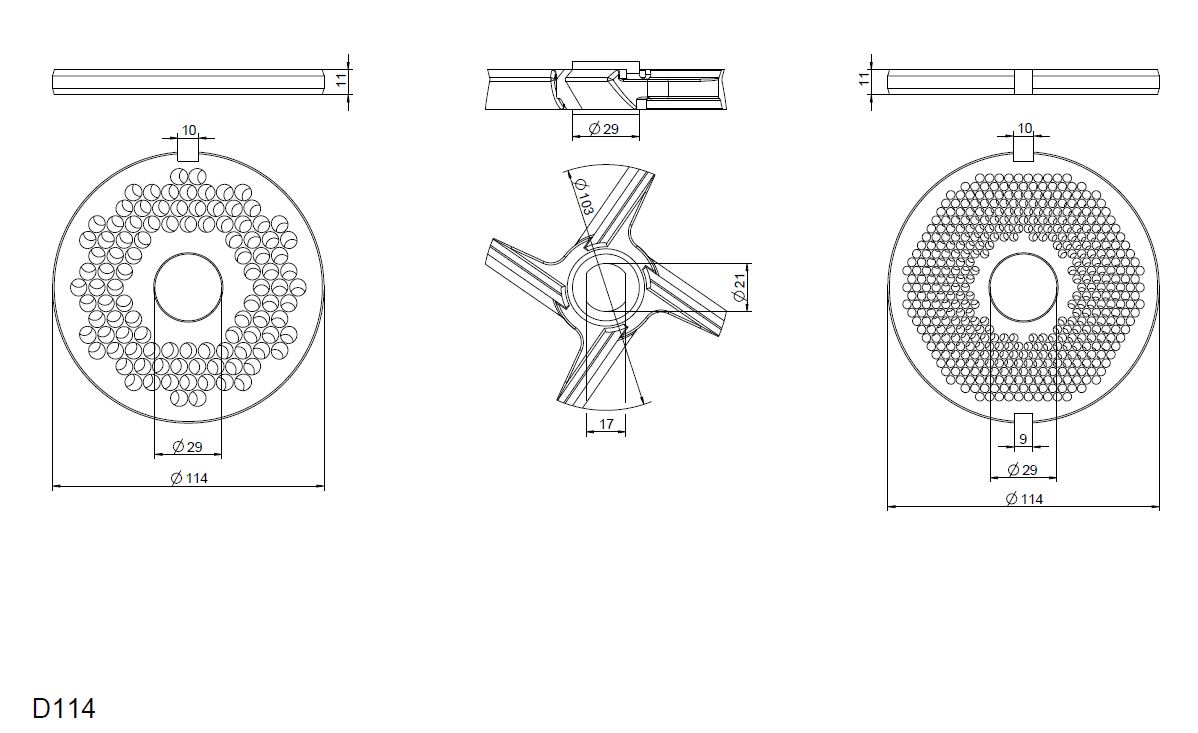

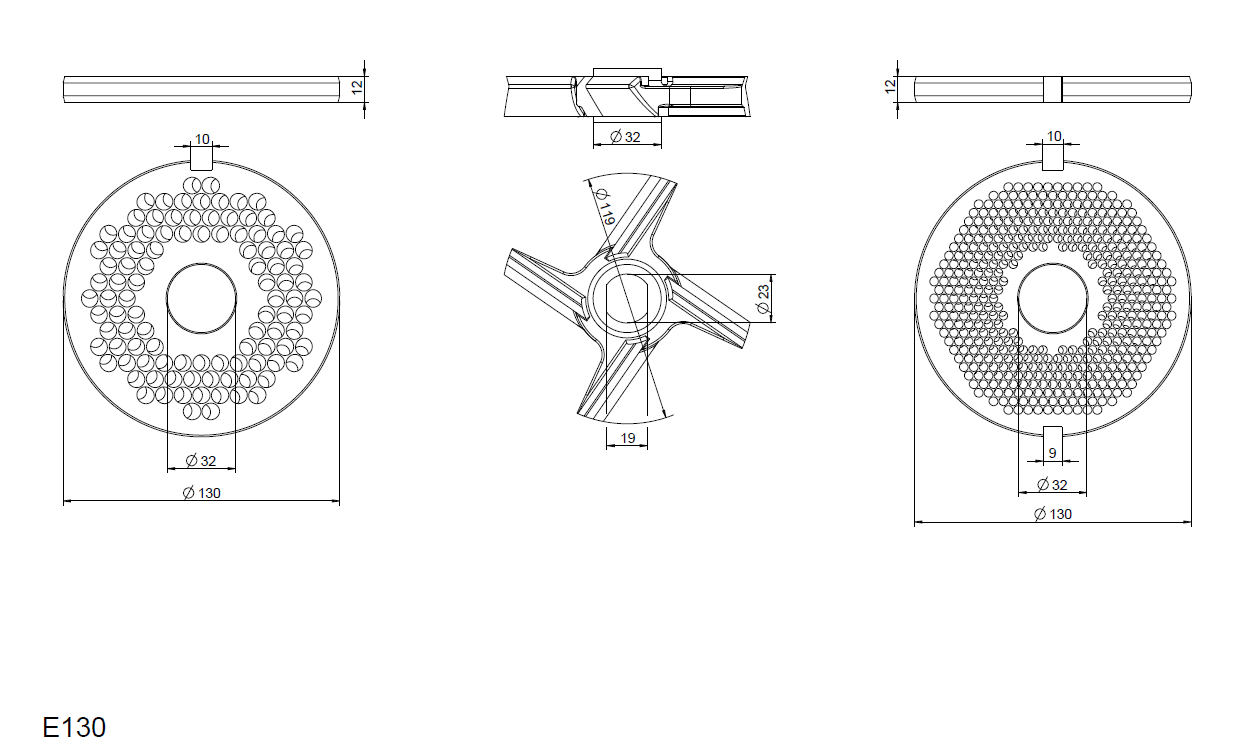

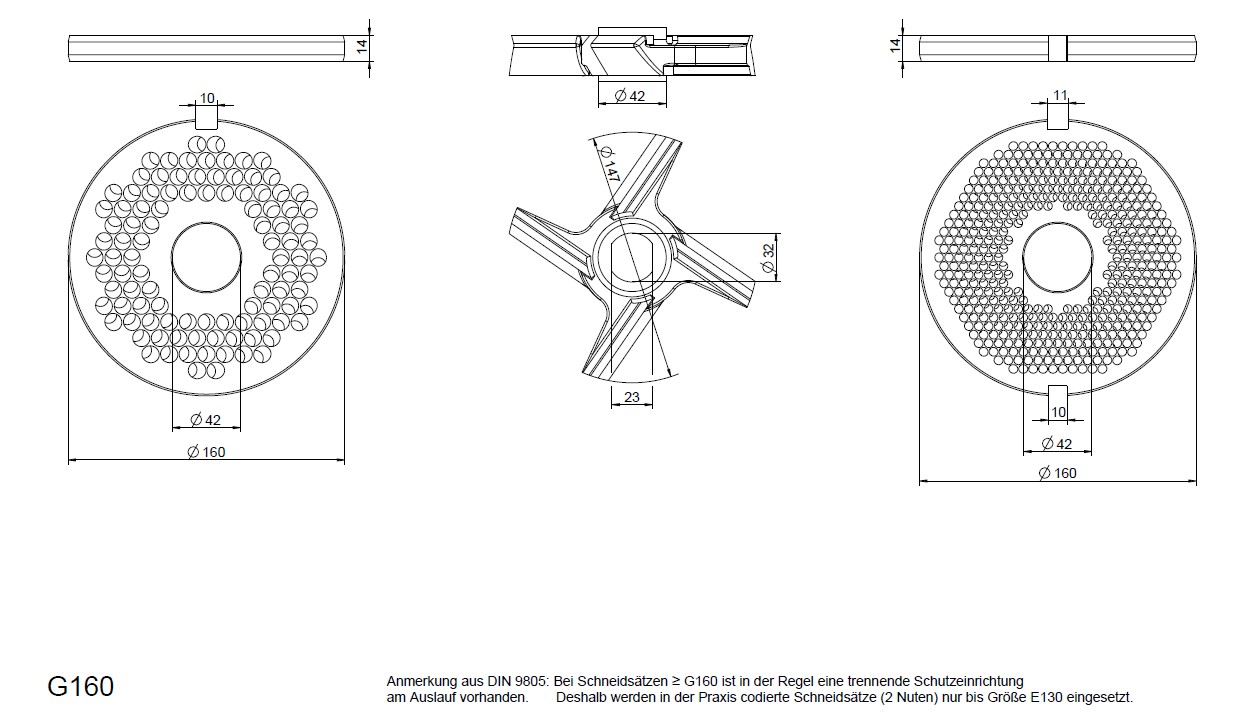

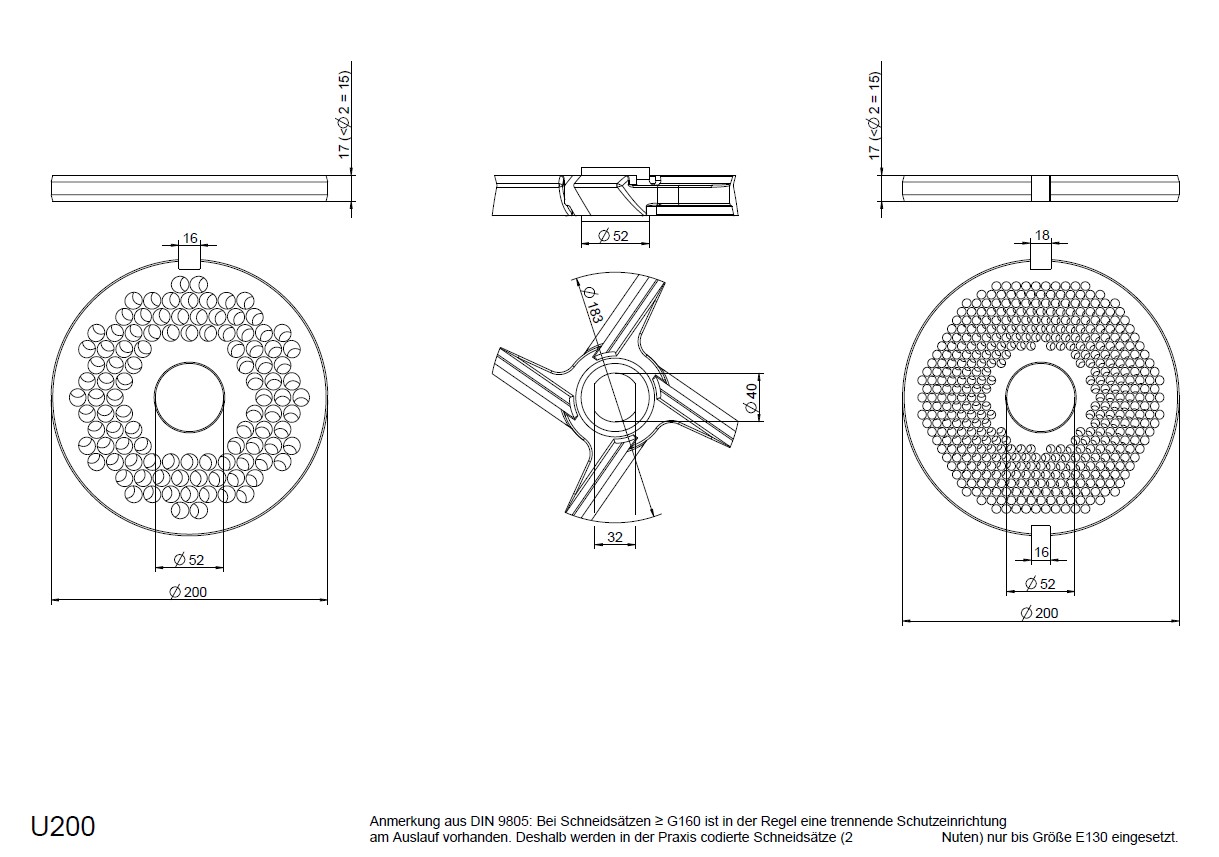

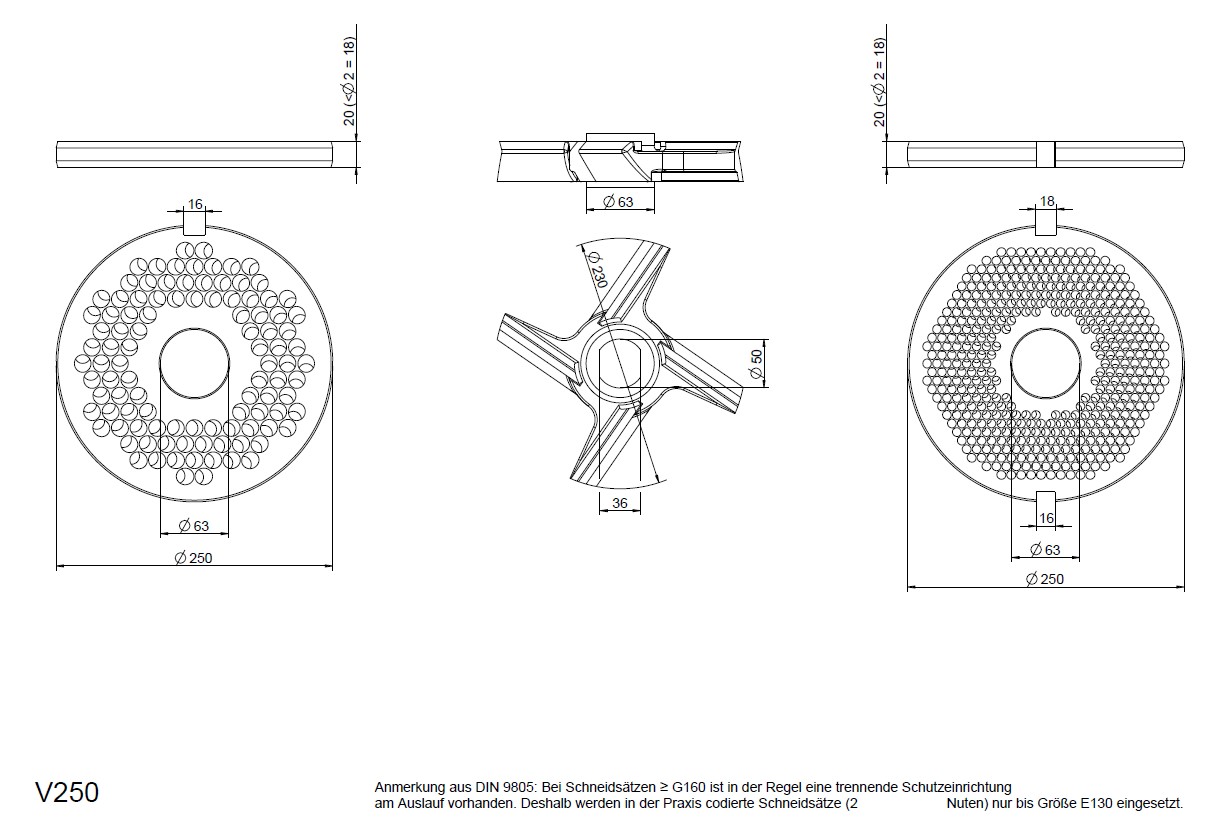

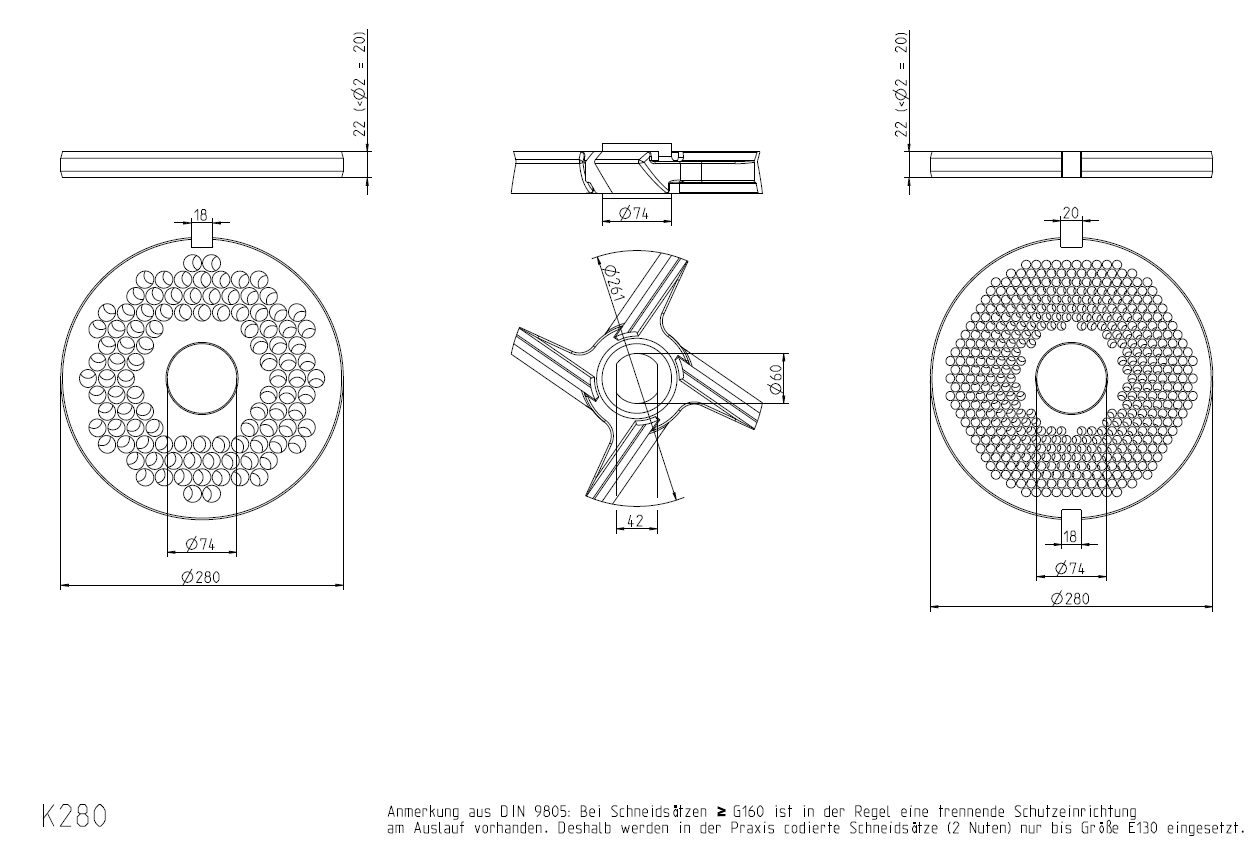

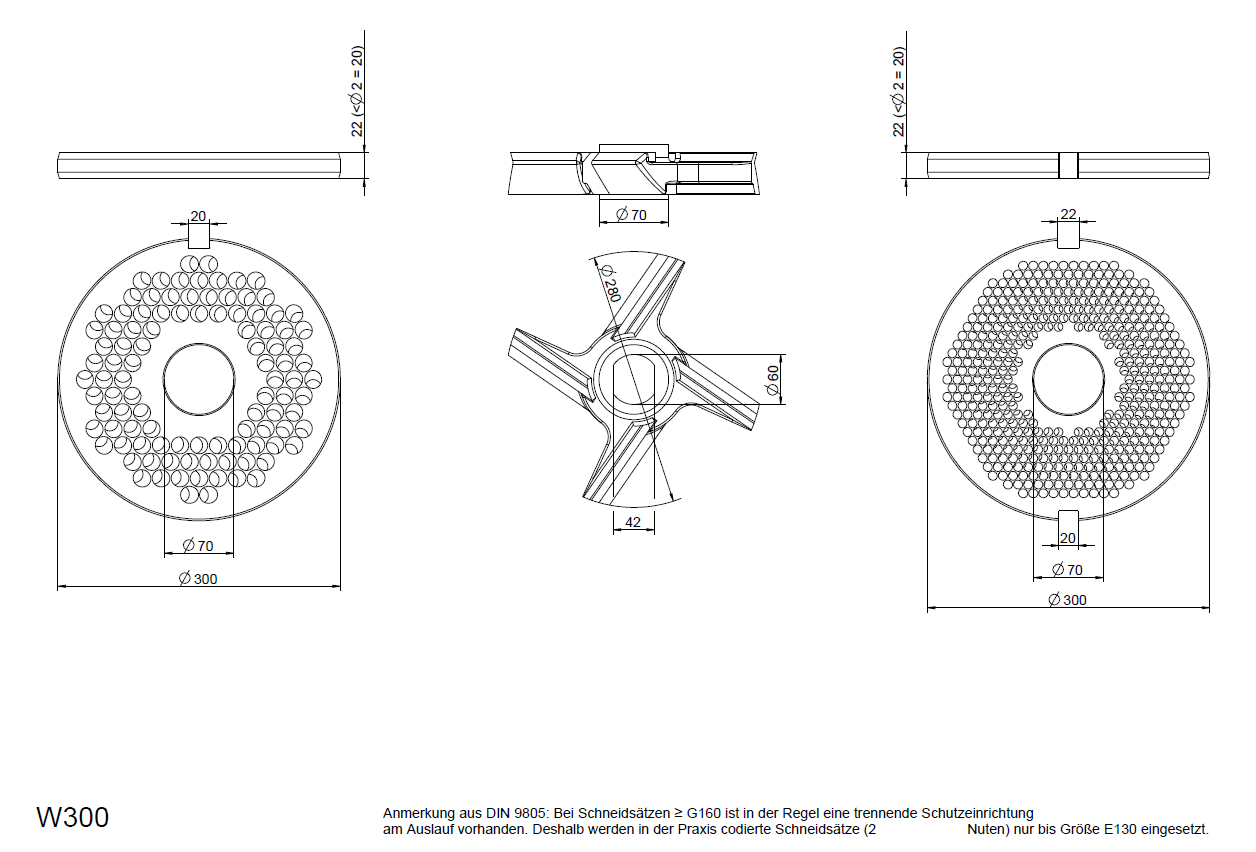

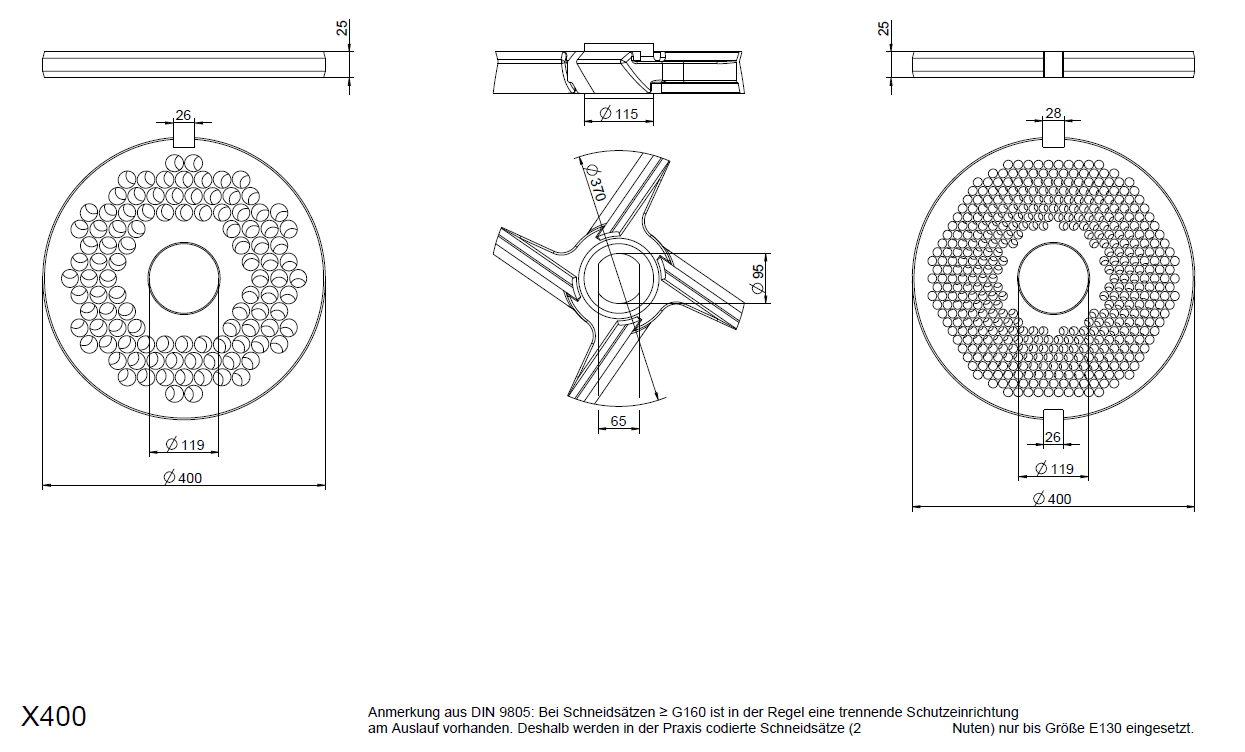

Technical specifications

A small overview from R70 to X400